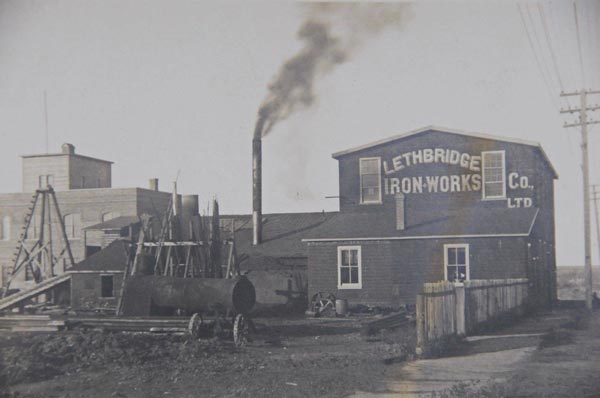

- Established in 1898 by D. Crichton & Son

- Located on the corner of 1st Ave and 1st St in downtown Lethbridge

- Operated as a grey iron foundry, machine shop, blacksmith, and fab shop

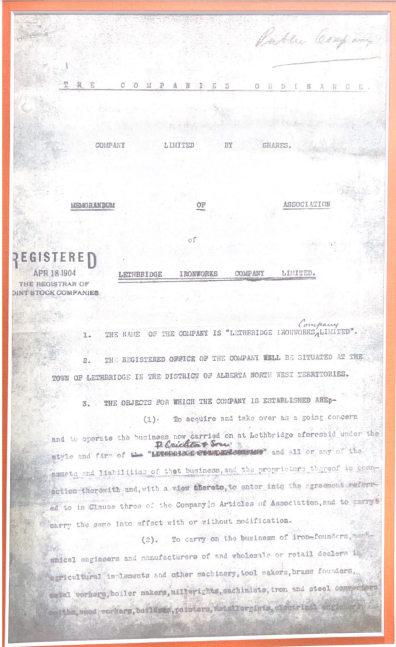

Lethbridge Iron Works Company Ltd. is formally incorporated in Lethbridge, Northwest Territories. Alberta didn’t become a province until 1905

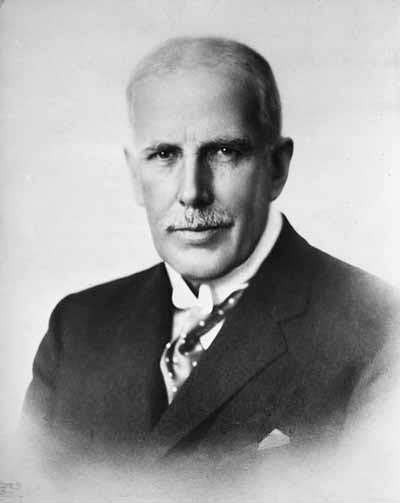

- The Crichton family sold their shares to Charles A Magrath.

- Magrath would go on to become Mayor of Lethbridge and a Member of Parliament.

- Both the main street of Lethbridge (Mayor Magrath Drive), and the town of Magrath 35km South of Lethbridge were named in his honour.

Seeing the employment potential of Lethbridge Iron Works, the city of Lethbridge provided the company with an additional plot of land with a 10-year tax exemption.

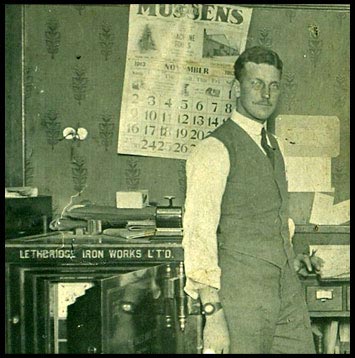

George B. Davies is brought in to manage the company, eventually becoming the 1st generation of Davies ownership.

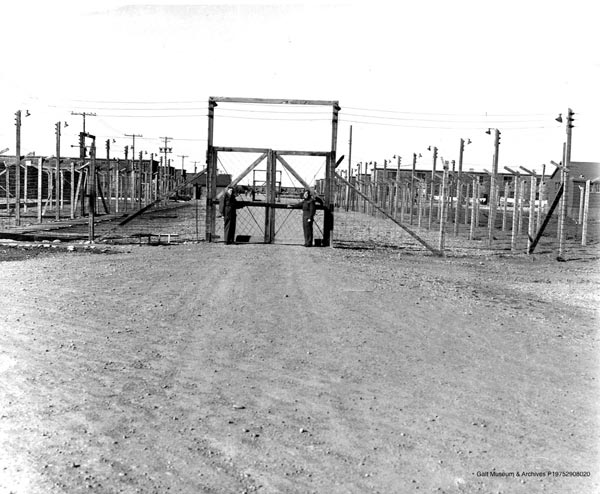

During WWII, Lethbridge became the site of North America’s second largest prisoner of war camp.

Decades after the war the long-vacant land that had been used for that camp was sold to the Davies family, and has been the home of Lethbridge Iron Works since 1974.

George B. Davies Sr retires, and George B. Davies Jr. takes over

Lethbridge Iron Works becomes licensed to produce Ni-resist and Ni-hard; cutting-edge abrasion-resistant alloys at the time. Both alloys have since been obsoleted in favour of High Chrome White Iron, Austempered Ductile Iron, and Carbidic Austempered Ductile Iron.

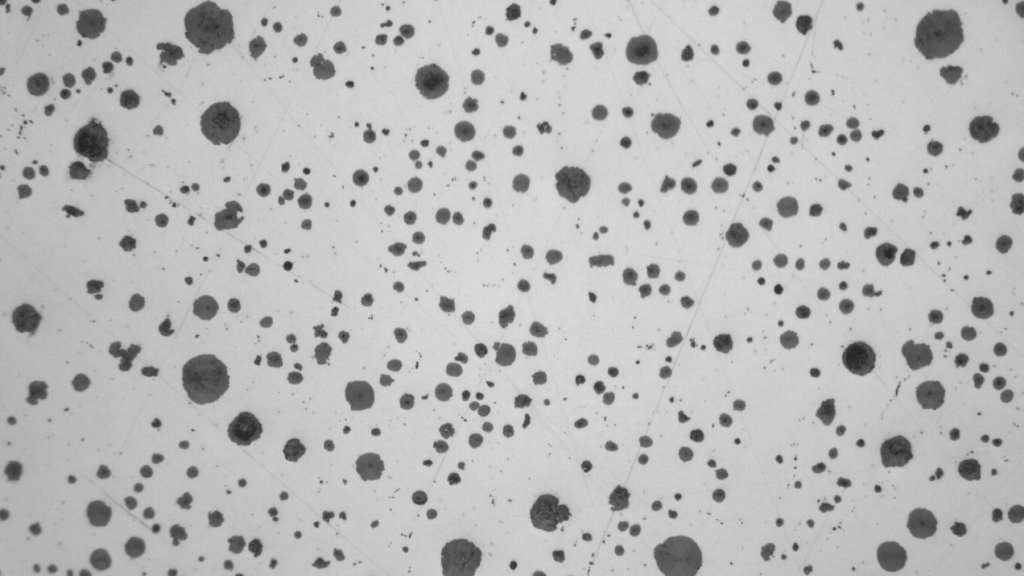

Lethbridge Iron Works became one of the first foundries in the world licensed to produce Ductile iron.

Today, ductile iron is over 80% of Leth Iron’s production.

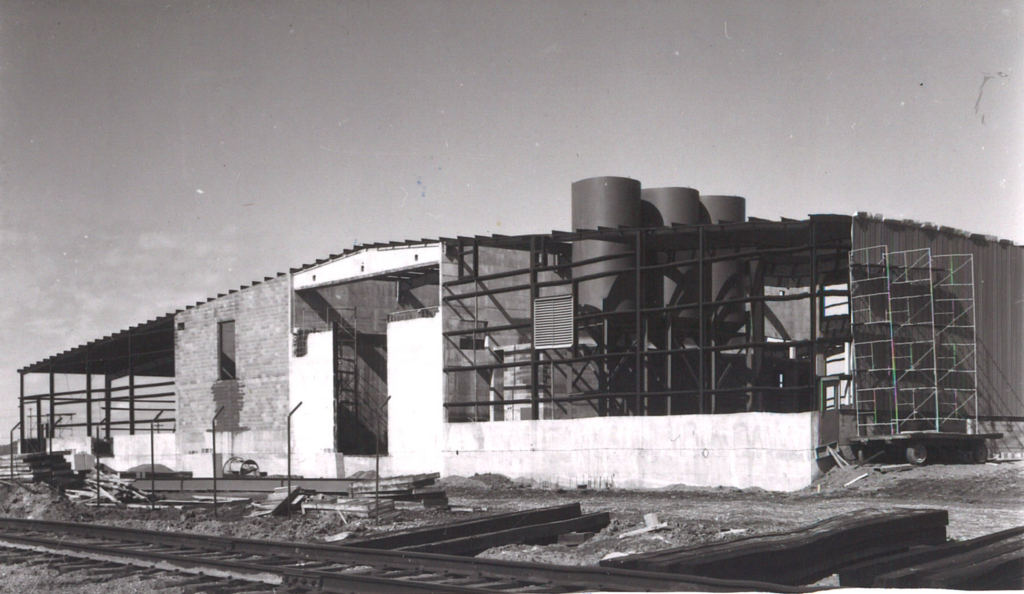

Lethbridge Iron Works breaks ground on a brand new 50,000 sq ft foundry in Lethbridge’s NE industrial park

The new foundry is completed, and Lethbridge Iron Works moves to its new home at 720 32 ST N in Lethbridge, Alberta.

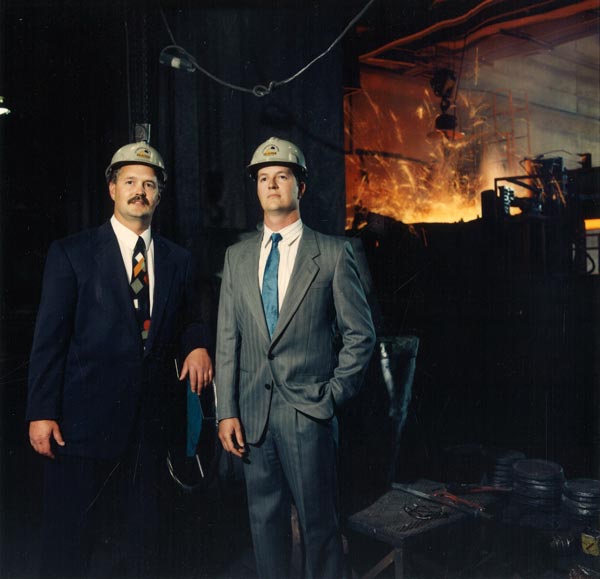

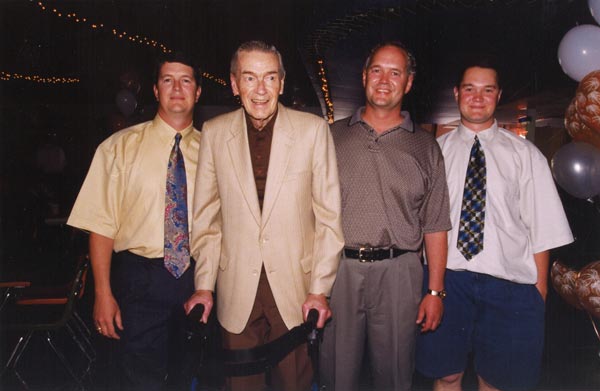

George B. Davies Jr steps back and his son Bart Davies takes over.

John Davies – The younger brother of Bart – joins the Executive team, using his education in engineering and computerization to usher in a new age of automation.

All equipment in the plant is computerized and converted to PLC’s

6400 sq ft addition built. The foundry also added:

-

- New dust collectors

- A Didion drum

- two shot blast machines

- six oscillating conveyors

Dylan Davies – the son of Bart – joins the company and becomes the 4th generation of Davies to work at Lethbridge Iron Works.

- 13000 sq ft addition built – Foundry now 80,000 sq ft

- Leth Iron becomes the first foundry in the world to install a Hunter model 20H moulding machine and model HLH-lll mould handling system

- Leth Iron installs a Foxall Robotic Grinding Cell, allowing castings to be ground precisely and repeatably with a significant reduction in labour.

- Shortly thereafter 5 more Foxall cells were installed bringing the current number of robotic grinders to 6.

Leth Iron builds an entirely new foundry facility on the property to house a SPOmatic automated moulding machine. With a flask size of 32”x44”x26”, the SPOmatic machine provides Leth Iron the ability to pour castings up to 500lbs at full production volumes.

Bart Davies retires, and his brother John Davies takes over as President

- A new core room is built, providing significant gains in core making efficiency.

- The foundry is now 110,000 sq ft under roof.

John Davies retires, and his nephew Dylan Davies takes over as President, becoming the 4th generation of Davies to run the company.

A dedicated sand plant using a continuous muller system is built and commissioned for the SPO foundry, ending the need for both the Hunter foundry and the SPO foundry to share sand production.

A 3rd Hunter-20 automated moulding machine is installed. With this addition Leth Iron now operates 2 Hunter-10’s, 3 Hunter-20’s, and a SPOmatic line.

Leth Iron is certified by Lloyd’s Register to produce marine-spec castings